Building an outdoor [mega] kitchen

What I learned during this process and what's left on completing this beautiful kitchen.

Somewhere around August, I told my wife that I was looking to do something with a 28’x10’ pad that the previous homeowners had in the backyard next to our pool area. We quickly discussed how nice it would be for entertaining guests, and I ran out with a tape measure to find out the dimensions of the area. Little did I know what an undertaking this would be—partly because of how I usually do things larger than life, and partly because Murphy’s Law seems to follow me everywhere.

Preplanning

Upon looking at the backyard, I decided it would be fantastic to go ahead and remove the Bradford Pear Trees in my backyard. At first thought, four large trees seemed like a great idea. However, after examining the ornamental pears that fall by the thousands into the pool, the age of the trees and how brittle they become at the end of their life span (these things were at least 20 years old), and the fact that a few of the limbs had already fallen way too close to the house a time or two when the wind picks up, this seemed like the right call. This would be the first step—getting rid of those trees would become the first thing that was done to the backyard in preparation for the project.

I remembered that my neighbor had a tree removed, and as I looked out at my backyard randomly one day, I saw the gentleman swinging from the tree he was cutting down with a chainsaw. He swung from limb to limb with grace, and as I watched in awe, the tree quickly came down. I called my neighbor and got the name of the person who had cut down the tree for him and called to ask for a price to remove the trees in my backyard. Removing trees close to a house isn’t cheap. I believe I was quoted $7,000 for the removal of the trees and trimming of the other three that are still in my front yard. This was a huge expense, but I felt like it was the right first move.

A few days after I had told the guy to get the trees cut down, I received a knock at the front door. The gentleman I opened the door to was an older man with a cigarette in his hand. He said, “I’m here to cut down your trees.” I showed him to the backyard, where he started climbing up the first tree. He began by trimming some of the smaller pieces off, and within a few minutes, he had the first tree nearly down. He had a small crew of two men (one of whom was his son) who began cutting the tree into small pieces and wheeling it out with my wheelbarrow that they had found sitting in the backyard. After just a few days of what I could only describe as a huge mess in my backyard, the yard started to return to normal, only without the trees that once guarded the backyard.

Finding the Contractor and Workers

Now that the trees were gone, we needed to find someone to serve as general contractor for the project. I had a general idea of what I wanted, but we had no clue about some of the details. Plus, I take on far too much to serve as the foreman of a few different crews. I remembered that the guy who remodeled our pool also built outdoor kitchens. He also served as the perfect mix of letting me do some of the work, while also knowing when to step in because I needed help. So I called Johnny and told him to come by.

While waiting for Johnny to show up, I asked myself what I wanted. I really didn’t know—we had tried coming up with ideas of what we liked. My wife had sent me hundreds of pictures from the internet that showed little glimpses of what I envisioned the perfect outdoor space to be, but none of them were “exactly what we wanted.” In my day job as an Engineering Manager, it always frustrates me to start building an “airplane while in flight,” so I knew I needed some general consensus on what we’d want and how to build it. I tried finding different programs on the computer, making basic sketches, and even using AI to help me build the perfect model of what I wanted, but none were great. As I brainstormed ideas of what I wanted, I knew a few things to be true:

• The far-right corner would be where I wanted my brick pizza oven.

• I wanted a place for my Big Green Egg.

• My wife wanted a grill of some sort.

• Research on the internet showed that a lot of outdoor kitchens don’t hook up to sewage, and I knew that I wanted mine to (especially since the drain clean-out was right next to the pad).

• A bar area to separate the kitchen area from the pool was a must.

• We have a lot of get-togethers, and I wanted a space that would be able to accommodate a large number of guests at once.

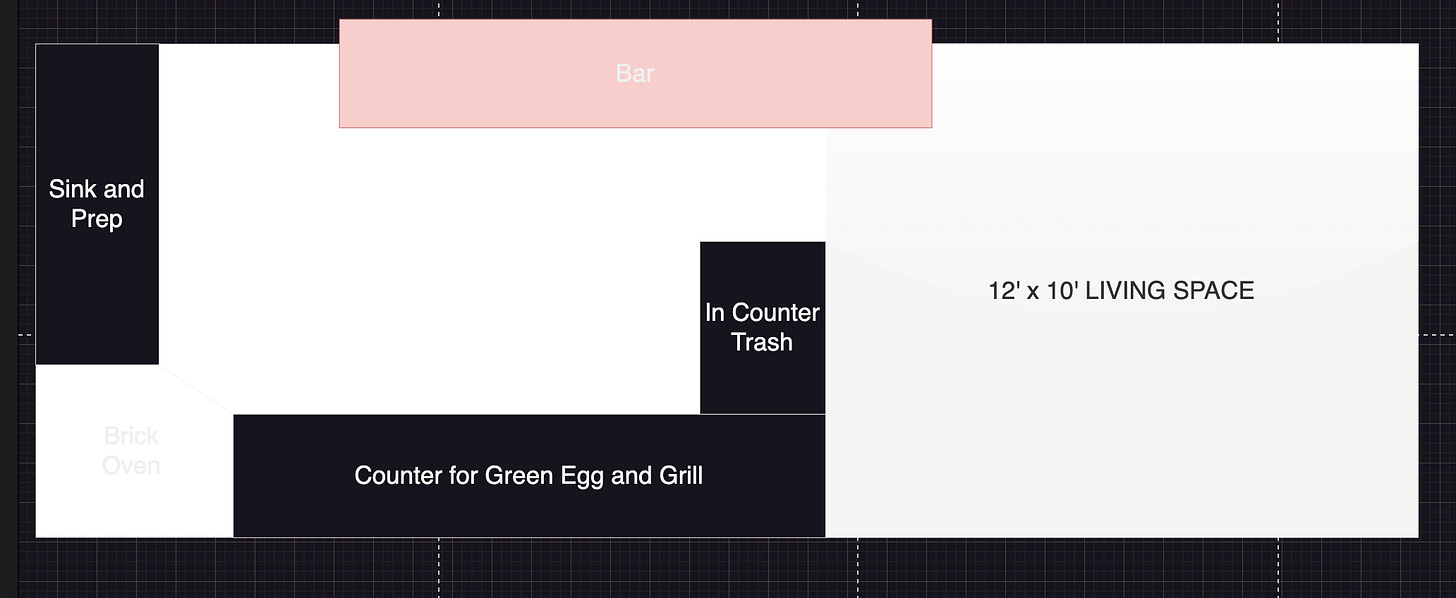

I opened draw.io and drafted a basic plan that I could show Johnny.

Building an Airplane in Flight

Not really thinking out all of the details was actually good. This allowed me to have Johnny give me suggestions that helped me with a better end product. I equated this to using an agile methodology and considered the above drawing my MVP version. When Johnny arrived, he had all sorts of questions that I hadn’t thought of and was probably overwhelmed by the number of things that I sent him that I had found on the internet or that AI had helped me draft up. Johnny also had his own suggestions that he was sending back to me, which created a really good brainstorming session.

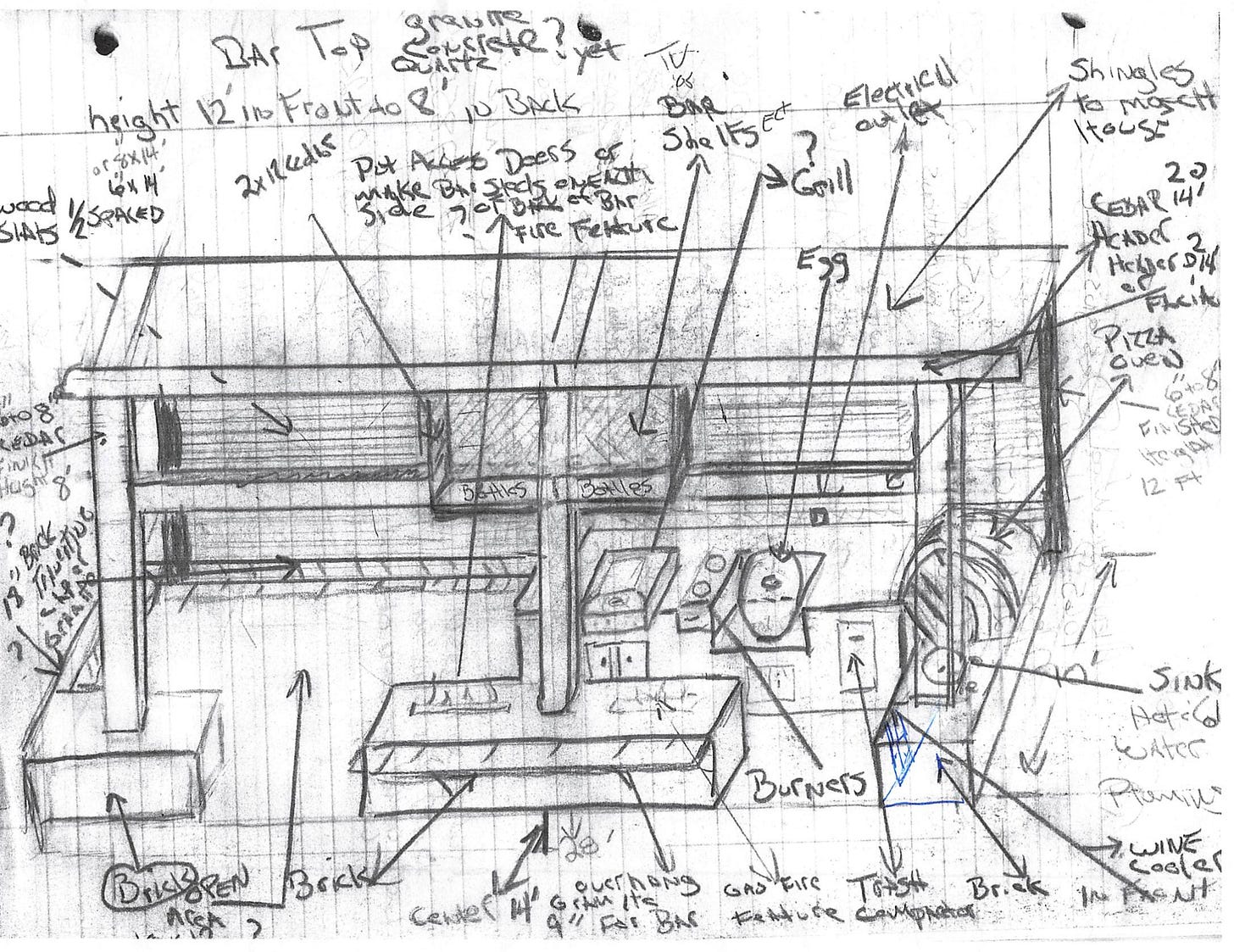

Fragments of the above were things I knew I wanted, but I also didn’t like other pieces, such as the backdrop (it just wasn’t our style). Johnny said he’d start drafting up a price quote and some ideas in a sketch. He said if I could draw something on the computer, that would be fine, but likely we’d just sketch something out on paper. I wanted very much to draw something up but also knew that finding the software to do this was already something that I’d spent hours on (trying new software, looking at website reviews, and even thinking about hiring someone on the internet to design this for me). Ultimately, the overwhelmingness of where to start always stood in my way. Johnny came by a few days after with a rough quote and told me that he could build something he’d sketched out on paper. I loved it immediately, while my wife had a harder time seeing the ultimate finished product from Johnny’s pencil-sketched drawing.

A Dream Taking Shape

After seeing the sketch and settling on a price (always negotiate the best deal you can, right?), Johnny told me to start looking for the equipment we’d be putting in the kitchen. He gave me a flyer for Bull Components, which offer some of the top commercial kitchen products out there. I started looking around, and I stumbled on the BBQ Guys website. After finding that BBQ Guys sold Bull-branded products along with several other very nice brands, I started looking for a grill and some other things. At around this point is where my wife swears that I blacked out, and when I came to, I had ordered entirely too many things (more on that later).

Ordering Equipment and Getting My Gas Turned Off

To get the best deal possible, I quickly signed up as a reseller for the BBQ Guys website using one of my LLCs that I do commercial property with (always negotiate the best deal you can, right?). I was shocked at how easy and quick it was to become a reseller. After completing the steps necessary, I ordered a few things for my outdoor kitchen. Johnny said we’d need to have them before we went too far with the plan to make sure we had room for everything.

In the meantime, Johnny had told me that it would take a few weeks but that he’d have craftsmen start showing up to do their part of the project. I told him that I’d use two local companies for plumbing (Blackburn Plumbing) and electrical (Big Game Electric). Johnny said that was fine and that it’d keep him from having to find someone. One day, around a week after Johnny had left, a crew showed up with a trencher to start digging the hole that we’d run power, gas, and water from. My wife had called the dig hotline to make sure that we were clear of anything, but they hadn’t arrived yet. I told the guys that, but they were adamant that they start on the trench because they had already rented the equipment. I left them to it and went back in the house for a Zoom meeting for work.

During the meeting, I started smelling a strong odor of gas, and not soon after, one of the workers knocked on the door and said, “We hit a gas line.” I didn’t know if it was a main or what, so I immediately called the gas company. The Oklahoma Natural Gas company quickly dispatched someone out (I’d say five minutes tops), and he turned my gas off entirely. I had already called Blackburn to get a quote, and miraculously they had shown up to witness the man taking the meter off of my house. The plumber told the guy he could put a cut-off in the backyard so that I would still have hot water in the house, and the ONG representative told me as soon as I did, he’d come back and turn the gas back on. Within hours, I was back up and running (with hot water). Never again will I let someone dig on my property without having it marked properly first.

The Pergola

A few days after the digging fiasco and having a quote for what was needed from my plumbers, I called Johnny asking him for daily updates. He told me that he had a guy coming out to build the covered part of the kitchen and that it was the first step. In the meantime he asked if I could pull a few bricks off of the flower garden wall to use to match the color of the brick. I had never thought about this, but it made sense that you’d want the brick to match, and that you’d need to have a brick to be able to match it to the ones available. Johnny assured me that he’d fix the broken bricks. Luckily I had a wall that surrounded my air conditioning units and they had the same color brick and some of it was already in need of repair, so I asked the guy who came to gather the bricks to take it out of there. He obliged, and went off to the find the brick.

Soon after, a man showed up to take some measurements of the pad (the pad was an already existing structure, if you’ll recall). He kept saying, “This is going to be a huge pergola,” and I was a bit nervous that he kept calling it a pergola (as Johnny had assured me it would be covered and weather-resistant). He told Johnny he’d call him with the final pricing and that he’d be back the following week to do the install. He asked me a few questions about designs and colors, and I told him mostly I wanted it to:

• Match what I currently had as far as colors in my backyard.

• Look professional and clean.

• Be made from cedar wood (I just love the look of cedar wood).

• Have a top on it so I wouldn’t get rained on if I was using the kitchen in bad weather.

Outside of those criteria, I told him I didn’t really care what it looked like as long as it was done right. He agreed and told me that he’d have them stain the boards before he came and that he’d be back the following week on Monday to start building. This is another lesson I learned: skilled craftsmen are almost never accurate with their estimates on time.

On Monday of the following week, Johnny called to say that they had found the bricks and that they were bringing them over the following day. Tuesday, they showed up with brick, and I became very excited because I could start seeing pieces of my vision come together. It was a lot of brick, and they stacked it neatly on the pad that would eventually become its forever home. The following Monday, the guy building the pergola showed up.

I had never seen so much treated and stained lumber. I was pretty impressed. The guy said they were getting started immediately and asked to leave his trailer in my driveway while they worked. Another lesson: when you build stuff, you and your family park on the street (I think my neighbors really appreciated the view of the cars).

The pergola guy and his helper (just two people) started jackhammering up part of the slab to make way for the columns that they would eventually erect for the structure. They even started setting the beams with concrete and nailing them together with what appeared to be throwaway boards.

They finished around 5 p.m. that day, saying, “We’re calling it a day and heading to get dinner before checking out the casino.” I remember running into them that night at Rib Crib and joking with them that if they ate too many ribs, they wouldn’t want to show up to get the job finished tomorrow. He quickly snapped back, “We’ll be there because we can’t leave town until the job is done.”

That morning, around 8 a.m., they showed up and started pulling wood off the truck. I was amazed at the speed at which they were working. Just those two men had gotten all of the beams set the day before, and all that was left was assembling the pieces on the truck. I remember thinking, man, this looks a bit larger than I thought it would, but I’m sure it will be fine. By the end of the day, they had moved a lot farther along than I had imagined them being. They did cut a large piece of our gas line to our pool heater, but the plumbers were already having to replace the line anyway since it had been cut previously.

By 2 p.m., they had made this start looking like a structure. I was still nervous that there was no top to this, but the guy kept assuring me it was coming. The next morning, at almost 9 a.m., I looked out to see the roof had been completed. It was so big and beautiful, almost mesmerizing when you looked at it.

Way Too Much Stuff

It was on this same day that a large truck pulled up to the house and started unloading pallets of things (this is where my wife gets the idea that I had blacked out somehow during the ordering process). I told her it was fine and probably mostly packaging.

This wouldn’t have been so bad if it would have stopped there, but the following day, the same driver made a delivery of equal size. He commented that we were becoming friends and he couldn’t wait to come back the next day, he said jokingly—or so he thought. Then, on the next day, another truckload arrived. When Johnny showed up to check the progress, he said, “Boy, you sure did buy a lot of stuff for this kitchen.” I think that was the first time I was a bit nervous, but I decided to stay calm and see where it all led. The bricklayers also said they couldn’t work on the kitchen while the brick was where it was, so they had to move all the brick over to the side of the pool.

Since the pergola guys were finished, Johnny let me know that they were going to come out to measure for all of the brick and stonework. I was so excited for this day. They started unboxing kitchen equipment for measurements. This was the first time I’d laid eyes on any of the commercial kitchen equipment.

After They Got Everything Out

After they got everything out, they told Johnny and me that there was a bit of a problem. We had too many pieces of equipment for the space we had allocated for the kitchen portion of the project. After some debating back and forth, I realized they were right and I had probably ordered too many things. Instead of trying to return them, I talked it over with my wife and we decided to do away with the sitting area of the kitchen and expand it out for more equipment (the amount I had originally ordered).

They got busy laying cinder blocks and then gave us an initial layout of what the kitchen would look like. These guys made laying brick look more like an art than a job. It was amazing to watch them work. Now that we had a base design, there were only a few changes that had to be made. Of course, we had to do away with the seating area, but we had also ordered a kegerator that hadn’t come in yet. There wasn’t a place for it. We decided that we’d put the kegerator under the bar, which would be pretty cool anyway. Since we were doing that, we’d have to give up the flame aspect of the bar because of space, but we decided that was okay. In exchange, we ordered one more piece of equipment (a wine fridge). After looking at the items that had come in, I took a quick inventory of the equipment we had/were getting:

• Stand for my XL Big Green Egg (I’ve had this for a few years).

• Counter doors for storage.

• Waterproof drawers for storage.

• Bull commercial 4-burner griddle.

• Angus (flagship grill of Bull) 75,000 BTU grill with rotisserie motor.

• Bull double slide-in dual side burner (with cover).

• Bull power burner with cover.

• 4.5 cu. ft. stainless steel Bull refrigerator (outdoor rated).

• 6.6 cu. ft. Bull kegerator (outdoor rated).

• Summerset 15-inch outdoor-rated dual-zone wine cooler - RFR-15WD.

• BBQGuys signature single-handle pull-down gooseneck hot/cold faucet - brushed nickel.

• Alfresco pot filler (outdoor rated) cold water faucet with double joint spout.

• 1-HP Evolution garbage disposal with automatic reverse.

• Pull-out trash cans (double).

How did I order this much stuff? Oh well, it was too late now (YOLO)! Things moved quickly after this. As the bricklayers worked on getting things measured and the foundation laid, we called Eric from Big Game Electric and had him start working on a quote for electrical. We also told Blackburn that we were ready for plumbing whenever they were. Over the next few days, the overall vision started coming into focus, and with what seemed to be very few problems. The only major thing that had happened was that the guys threw a breaker on one of my smart switches by plugging in a power saw to one of my outlets—it was a quick fix, and after resetting everything, that was off started working again.

Now There Was Foundation

Now there was foundation laid for everything that was going in the back part of the kitchen (still no bar area yet). I remember Johnny was a bit mad that the guys had used smaller cinder blocks but said ultimately it would be fine; they would just need to make sure it was reinforced well (which they did). As they started laying actual brick and not just blocks, the kitchen started shaping up nicely.

It became a joke with my friends and co-workers to ask the status of the massive kitchen. It even became a norm for me to post weekly updates about what had happened on the kitchen progress, and people were starting to have major buy-in on how it was coming along. One day, I even saw my neighbor, Brandon, in my backyard on the camera with his wife and dog. I laughed because he was simply showing her what was going on. Neighbors began asking, “Why are you always parked outside of the gate? What are you building over there?” People came at all hours of the day, showed up on Saturdays, and made lots of noise while we tried to sleep in, but the kitchen was forming out nicely.

On October 9th, at around 5 p.m., the bricklayers finished the stonework on the front, had started the bar area foundation, and were figuring out how many fire bricks would be needed to construct the pizza oven. We had gone back and forth on how the pizza oven should look. Johnny had ideas, I had ideas, and the builders had ideas. Ultimately, as we went over to a friend’s house to see their pizza oven, she said that a smaller oven wasn’t the worst thing, as the pizza oven could heat up faster this way. This made us change the shape from a large dome to one like the above pictured from my work colleague.

The Sewer Backup

It was on this day when Heather came into my office and said that the kitchen sink was “gurgling.” I looked around and then walked outside over to the clean-out right next to the trench that had been dug. Water and sewage were pouring from the hole as Heather ran the washer and worked in the house. I went and got my trusty pressure hose, stuck it down the hole, and unclogged the drain—at least for now. I noticed they had unscrewed the cap to the clean-out, and as I looked down, I saw why. It wasn’t just because the cap was off; the cap was busted. The guys who dug the trench likely ran over it and then just didn’t say anything. It was an easy fix, and my neighbor had an extra cap, so I unscrewed the old cap and sent a picture to Johnny exclaiming that the workers had broken the old one.

Unclogging the drain also busted my pressure fitting, so I added it to my mental list of things that needed to be picked up on my next (usually daily at this point) trip to Lowe’s.

Things were good again until October 11th. This was the day that the drain backed up, but this time, since I had replaced the cap, the sewage ran back into the master bathroom bathtub and came out onto the bathroom floor. I immediately went back out and took the cap off to relieve the pressure. We (the workers, me, and my neighbor) tried for a few hours to unclog the drain but had no luck. We ended up calling Blackburn out. It was 4:58 p.m. on a Friday afternoon when they showed up. After several attempts to unclog the drain, he finally got it. He did say he thought that since this had happened a few times, there was a bigger problem, possibly one of the lines under the ground had become disconnected with all the trenching. He said he’d come back Monday to fix it correctly, but we could use the plumbing for liquids only for the time being.

Progress Must Continue

This was terrible. We had to take the kids to go #2 up to my commercial property, and they never seemed to all need to use the bathroom at the same time, so it became almost an every-few-hours thing. On the bright side, they had gotten the pizza oven shaped, and it was looking quite nice. They had also installed the metal braces that would hold the rest of the equipment. I remember thinking that was the silver lining to all of this.

Not knowing what to do or what the cause of the plumbing issue was, Johnny hired a worker to come over on the weekend to “dig a hole” to see if we could find where it was disconnected. I remember walking out and seeing a 5’4” man in a 7-foot hole. A rather large hole in the backyard. He was digging down and said he could not find any place where the pipe had come undone. Then it hit me like a freight train—they didn’t just bust the cap; they had clogged the drain with the busted part of the cap. I was certain this was the case. Johnny said he couldn’t possibly figure out why the house was backing up, as they hadn’t touched any of the plumbing, and that the cap was busted weeks ago, so it shouldn’t have been the problem. I remember telling him that I’d be happy to pay the bill when the plumber came out and said it was not the cap that was clogging the toilet. We ended up getting a worker to disconnect the line from the city main, and lo and behold, there sat the cap. Perfectly fitting to the edges of the hole that went into the city main. This was why liquid waste flowed easily—it would raise up and let liquids through, but not solids. I was elated to know that I had correctly diagnosed the plumbing issue. Had I missed my calling? Was plumbing what I should have been doing all these years instead of technology? As that thought quickly faded out of existence, I sent a text to Johnny showing him the cap sitting on the hookup to the city.

Now that we had the problem identified, all we had to do was get the line back on. This seemed like it was going to be a simple task, but simple and me never quite go hand in hand. As the worker was sitting the line back on, the line that had been buried years back and had been sitting at an angle with all kinds of pressure, he couldn’t quite get it over far enough. I was watching him as he started trying to pry it over with a shovel to get those extra few inches he needed when suddenly I heard “SNAP!” The main sewer pipe to my house just snapped off in the ground. More digging ensued. At this point, I was getting frustrated with the worker (who is a great guy), and so I left to cool down. He couldn’t quite get everything to line back up with the new pipe he had bought, so he sent me to Lowe’s for a few different connectors. I remember that I couldn’t find a “T” pipe, but I did manage to find a “Y,” which has a directional curve to it to allow plumbers easier access now in the hole. Of course, Niko (the worker) put the “Y” in backward. I told Johnny I wanted a professional plumber to at least look at the work and “sign off” on it before we covered the hole back up. I wasn’t going to leave this to fate, as we had already experienced way more house problems from this project than I had expected or ever wanted. Even without a plumber signing off, at least we could use the bathroom at our house once more.

The fiasco above didn’t stop progress. Nothing seems to be more true than if you have one or two people working on something, more show up needing to work in that exact same area. On this particular day, Big Game showed up to run electricity and to go ahead and run some extra conduit they’d need later on. As they worked, so did the bricklayers, continuing on the pizza oven.

Scope Creep

Eric, from Big Game, suggested, “Hey, since we are already running electric over here anyway, you should have those guys pour you a pad eventually and move your hot tub over to the more secluded area behind the pergola and the cubby of the house.” I’d never thought about it, but I did hate where the hot tub was at the time. It sat right by the window of the outside bathroom, which always felt “odd.” I told him to go ahead and run the 220V cable in conduit, and we’d at least have it there when we decided to do it. My wife heard this idea, and as she said, “I love that idea,” I knew it was only a matter of time before the next words came out of my mouth: “Johnny, go ahead and get me a quote on pouring a pad for the hot tub over there.”

Since I was installing the new pad and knew that I’d have concrete guys working, I also went ahead and ordered something I’d been eyeing on the internet for a while. I wanted a palm tree in the backyard. We had ordered four thus far, and none of them survived our Oklahoma climate. I found a company online through targeted marketing tactics on Facebook called Desert Steel a few weeks prior and had ordered some metal agave plants for our pool planters. They looked realistic, and so I kept teetering on ordering one of their metal palm trees. That night, I checked out and had a metal palm tree coming my way!

That afternoon, around 8:00 p.m., I remember going out and looking at the pizza oven. It was perfect on the inside, but the smoke stack on top was going to be something that I envisioned blowing black smoke all over my cedar wood. I would need them to fix this eventually, but for now, it was great.

They told me to burn it in with hot wood so that they could make sure there were no problems. I couldn’t wait.

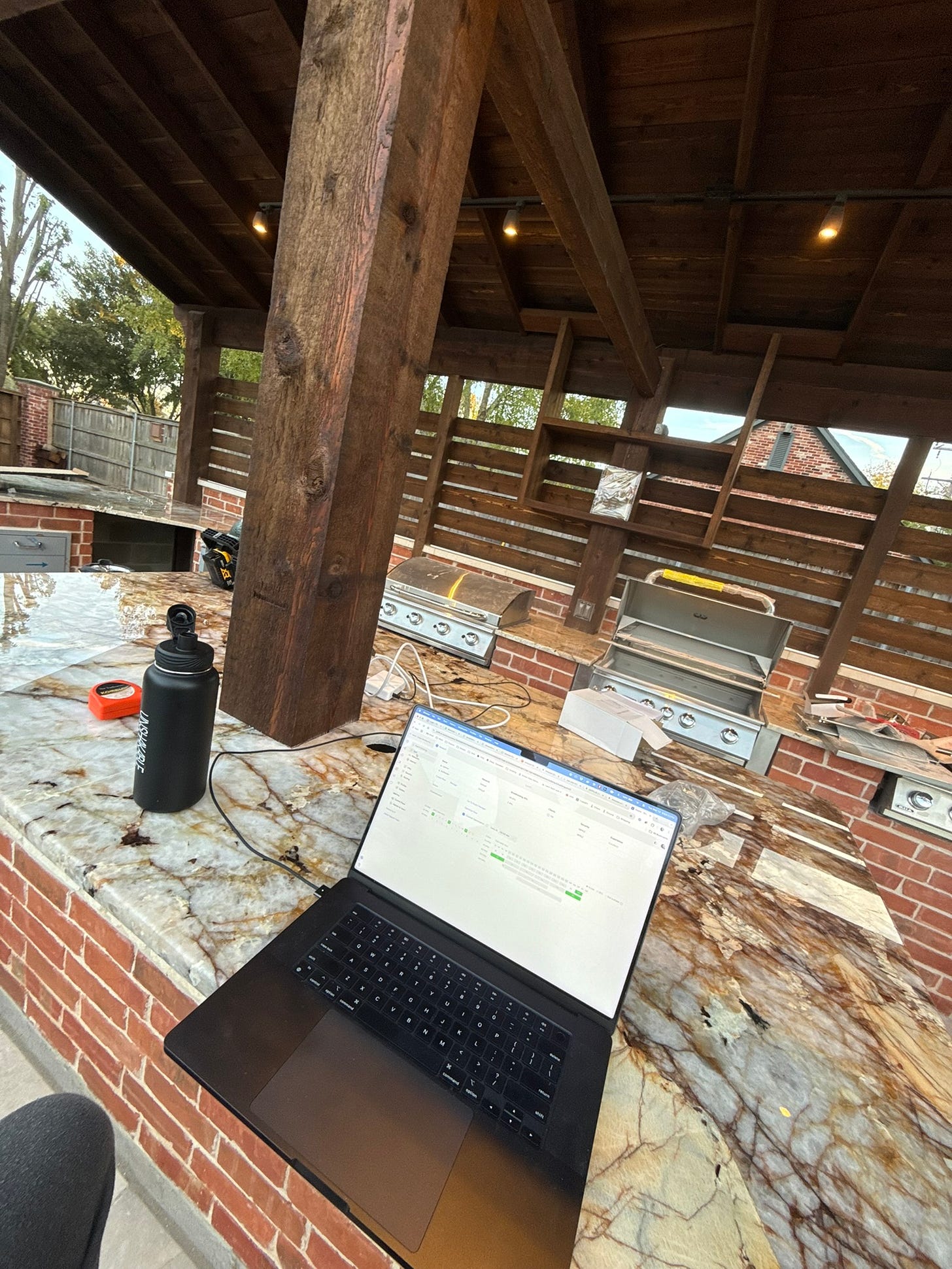

I got back on Sunday afternoon, and to my shock, they had finished the bar. It looked fabulous. They had also placed most of the equipment in its final places. This was really starting to look like the outdoor kitchen I had dreamed of.

The following week was Fall break for the kids, so we took off and headed to Boston for a quick getaway. I left so much undone and couldn’t help constantly thinking about what I needed to do first thing when I got home. I couldn’t wait to try out the new equipment. I went ahead and called Blackburn, and they did have a few small things they wanted to fix on the plumbing. He was done within a few hours. While he was there, I told him I was ready to hook up the equipment. He said he’d be back later that week, and I told him I was out of town, so absolutely no rush.

Let There Be Light

We returned on October 25th to find that they had installed the track lighting in the kitchen and that Eric had done a fantastic job hiding all the electrical inside the wooden beams. It was small black wire, but still black wire I didn’t have to notice every time I looked over at the kitchen. Little details like this are what make something fabulous look extraordinary. The guys had also set my Big Green Egg in its new home and cleaned up a lot of things. The big hole still remained, but this was really coming together.

The Tree Is Coming

That week, I received a call from a Kansas number. I answered, and it was the owner of Desert Steel calling to thank me for my order and tell me he was shipping it out. He said if I had bought the bigger tree, it would have had to be delivered by a moving company, so he thought the size I had got was the perfect one. I couldn’t wait for it to come in.

A few days went by, and then the massive tree arrived via freight truck. It was a major ordeal to get off the truck. With the help of Brandon, my incredible neighbor, we put it in the driveway (still parking on the street at this point). The tree was very well packaged and looked more like a piece of furniture than a tree. I could see why the instructions suggested anchoring it into concrete.

Burning in the Pizza Oven (Part 1)

The next weekend, my father-in-law, Frank, brought me some firewood he had cut specifically for the pizza oven. It was post oak that was less than two inches in diameter. The small pieces were great for throwing in the fire as needed. We fired up the test fire to see how it’d work.

The smoke was definitely an issue, as I had suspected it would be. We also saw right away that the oven opening was too big, allowing most of the heat to escape out of the front of the pizza oven. I noted these things down for Johnny to take care of the following week.

Originally, Heather had asked Johnny if we could be done by Halloween. He laughed and said, “Sure,” but then explained it would likely be closer to Thanksgiving. On Halloween day, they did manage to get the concrete poured for the hot tub, and they were able to get the tree put together for me. Wow, this tree looked awesome (remember, little things set off projects)!

The Tree Is “Planted”

The project was grossly over budget. I remember thinking, “When will this be over?” It was about this time that Johnny found a granite vendor and asked him to come and measure for the kitchen.

We had also decided to have the kitchen area and the hot tub area “cool decked,” which meant another Saturday of being woken by the sound of a jackhammer busting up the existing concrete so that the cool deck would adhere better. This would ultimately match the rest of the backyard around the pool.

Time for Granite

Around November 2nd, a man came out and measured our kitchen area and talked to us about different types of bevels and finishes for the granite. Overhang, thickness—there is a lot to granite for sure. After he had measured, he told us to drive over to his place (about an hour and a half away) and pick our granite. We headed over that Friday to figure out what we wanted.

As we drove in, we saw the prettiest piece of granite. Heather immediately fell in love with it and said she loved that one.

Of course, it was the most expensive one on the lot, but YOLO, right? After looking at every single rock on the property, we decided that the first one we saw was the right one for us. Johnny had given us an allowance for the granite, but we quickly exceeded that number with this fabulous stone. When I told Johnny on the phone, he said, “Boy, you sure do have expensive tastes.” I laughed and said, “Yes, in women—I married her!” We laughed and talked about a few other things we wanted to get done. One thing I had asked Johnny to add was a pool filler. Johnny had built our original pool, but we forgot to add a pool filler. This meant that I was the “pool filler.” I’d much rather this be automatic, so Johnny had brought out a pool filler to go into the ground where we were running the water to the kitchen. It just needed to be installed and was going to be done this week. I reminded Johnny about the problems I had witnessed with the pizza oven as well.

A New Plan for the Pizza Oven

It was also around this time that they came back and fixed the brick pizza oven by closing up some of the front to keep more of the heat in. I also ordered a thermostat for it and drilled a small hole in the mortar for it to insert into. This would give me real-time readings on the pizza oven, as I had been told you needed to get the oven up to temps over 750°F. I wanted to measure this with something other than a heat gun.

While the guys were there fixing the pizza oven, they also bricked back the bricks they had removed and did an even better job by patching some of the older brickwork that was losing mortar. This was fabulous.

Hot Tub Movement

The following weeks were a bit slow for progress. We waited on the stone to come in, and we still needed to move the hot tub over to the new pad. I told Johnny I could help with that, and he brought his partner in the pool business to help. We also enlisted, yep, you guessed it, Brandon! After about an hour, we were able to get it lifted into place, and it looked fantastic.

I remember thinking, “Oh, now I want to cover it too.” Then quickly remembered, “You’re over budget, Chris,” so I decided to come back to it later on (perhaps another post on that in the coming year). We still needed to get it hooked up, but out of sheer coincidence, Eric and Chase came over from Big Game that day to do some other work and went ahead and ran the power for the hot tub as well. It needed cleaning, so I asked Johnny to leave his shop vac so that I could get it ready for water.

Heather, Come Quick, It’s Glowing!

That Monday, a truck showed up with granite on it. I remember seeing the granite on the truck and stopping to notice something new about it. Some of it was translucent to the light of the sun. I ran back in the house to show Heather, as I knew she’d be so excited about it.

I wondered, “Could you put some lights under that and make it glow in the dark?” I’d have to try that after they had it fully installed. These guys moved so quickly. They had it done within a few hours.

I was so excited that I worked out on the bar area the entire rest of the afternoon. The guys were asking me questions about where holes needed to be drilled, etc., anyway, so it would have been more of a distraction to walk back and forth from my office.

They also installed the sink under the granite and cut the holes for the faucet. Eric had ordered some fancy in-counter plug-ins, so we had them go ahead and cut the holes for those too.

That evening, I went and took out my Dewalt battery-powered light and put it under the counter. It was beautiful.

I immediately went to work searching the internet for granite underlighting. There weren’t a lot of hits for that search term, but I found a few contenders. The best one looked to be either SLABlite or Light Tape. Most people did recommend installing these before you installed the granite, though. That afternoon, I called Eric to ask if he had any experience, and he did. Much to my amusement, he recommended SLABlite to me. He said, “I have to come over to hook up the disposal for you and put a few of the lights in this afternoon, so I’ll bring a SLABlite I have at the house from a previous job that you can try out.” The test SLABlite was fantastic, but it was an older model, which didn’t get quite as bright as I had wanted. Ultimately, I decided to do this later after I was closer to being finished with the current projects for the kitchen.

More Small Touches

Eric outdid himself on the electrical. Everything was so well hidden. You couldn’t even tell where things were coming from. Little things absolutely were setting the project apart from other kitchens I had seen. While he was there, he also installed lighting for the palm tree that comes on with a photocell. This really highlighted the backyard.

I can’t say enough good things about Desert Steel and highly recommend their products to anyone who wants to either enhance their real plants with others that don’t grow in the area or just wants something they don’t have to worry about keeping alive.

The Pizza Oven Burn-In (Part 2)

The project was moving along nicely, and it was finally time to test the pizza oven once again, especially since they had installed a new exhaust pipe for the smoke.

Even More Small Touches

Johnny and I fidgeted with the pot filler, making it look as good as we could since we had them leave the copper pipe coming up out of the granite for aesthetics. We thought it looked rustic and would be a great way to show off the pot filler.

We had a little work to do on it, but we were building a box to let it sit on, so it looked like it was coming out of the wall. I laughed as I thought to myself how much it reminded me of a birdhouse. The bricklayers also came back and filled in the back of the walls to marry the brick to the granite. We also had someone come and caulk all of the seams to make them look even better.

I had my daughter pull off all the plastic wrap. I don’t think either of us realized how long that would take, but things looked fantastic. We did find out that we didn’t cut a spot in the granite for the rotisserie, but the guys who did the granite job were so kind to come back over and cut that into the granite for us.

We did have to take out the Green Egg to get the plastic off. This was more of a task than expected, but it came out so nice that we didn’t mind.

Time to Play

That night, we told Johnny we were going to cook steaks the next day in celebration of the new equipment. He laughed and said, “I want mine medium rare.” We obliged! Along with steaks, we cooked mac and cheese, potatoes, and garlic bread—all in the new kitchen. We were so excited, even though we didn’t really have everything quite ready. It’s always fun to stop and play a bit.

The steaks were a huge hit. Johnny ate with us and said it was the best steak he’d had in a good while. We had a little more work to do, but we were getting close to the end of the daily rat race of people being at our house. I had bought a router and, with the help of Brandon, had decided to install some Hue lights into the wood. I didn’t want to mess this up, as there is no going back, so we practiced over and over on spare pieces of wood until we felt like we had a process down for installing the track I had ordered on Amazon.

Measure Thrice, Cut Once

This took longer than expected. The track and the Hue lights said they were made for each other, but they were a little smaller than originally thought, making the Hue lightstrip hard to insert into the track (which, to my surprise, fit right in the groove I had routed out using a handheld battery-operated router and a 4-foot level—Brandon’s level). I ended up having to cut the plastic protection piece off the Hue lights and then rig them to fit in the track by placing some of the rubber back in to insulate the strip from the metal. I drilled a hole in the end of the strip and ran the cables around the back of the structure. This was fantastic. I couldn’t believe it worked as well as it did. I now had some mood lighting that I could change as often as I wanted. I ordered three more of these, but to date, I haven’t installed them in the wood yet, as it takes about four hours to get everything perfect, and you want it to be perfect!

On the same day I was cutting the wood for the LED strip lighting, the folks from Bugs R Gone came out and installed mosquito repellant nozzles on top of the pergola. They installed a cutoff switch to them so that the rest of my backyard could be sprayed on a timer without spraying guests and food if I’m entertaining. I’ve had the system in the backyard for a few years now, and it costs about $350/year to keep mosquitoes, dirt daubers, wasps, and flies out of my backyard (well worth it). You can see the tiny nozzles in the picture below on the very top of the overhang.

Thanksgiving

Thanksgiving had arrived, and we were pretty much done with the kitchen. We ended up cooking a turkey in the Big Green Egg and some chickens on the rotisserie! Everyone raved about the chickens.

That afternoon, we tested out a brisket on the Egg just so we didn’t have to eat more Thanksgiving food. The results were fantastic, and we shared it with our family.

The Pizza Oven Fiasco (Part 3)

The night after Thanksgiving, we invited some friends over to test out our pizza oven and pizza-making skills. As Heather prepared by making pizza dough from the special pizza flour we had bought, I was outside getting the pizza oven hot enough. If you’ll remember, circa 750°F was recommended, and I had just bought a new fire stoker from Kopper Kettle (a local kitchen store) that I wanted to test out. I filled the pizza oven with as much wood as I could and then started my fire. It was roaring, and it was fabulous. The new stovepipe was making it so I could stand by the pizza oven and not get smoked out. The new front was keeping the heat in. The stovepipe looked fantastic, as they had painted it black with high-temp paint. It was a lot taller than they had anticipated, so I had asked Johnny to use metal tape to hold it to the pergola. None of us thought about what would happen if the heat got too high.

And then it happened. As I was getting the heat higher and higher, it eventually hit almost 850°F. I looked up to see the stovepipe glittering. At first, I thought I was imagining things, but then I started seeing the glitter ignite into fire and fall from the stovepipe. The high-temp paint had caught fire. I immediately thought, “If this happened on the bottom of the pipe, I hope it didn’t happen on the top too.” I ran around to see the top of the stovepipe engulfed in flames. And then the side of the pergola started glowing too. It was a matter of moments before the whole pergola would be engulfed in flames. I remember thinking, “You idiot, you’re gonna burn this thing down, and you haven’t even cooked a pizza in it yet.” I was panicked. I reached for the sink and pulled the faucet as far as it would go and switched it to spray. The water came within inches of the flame but wouldn’t quite reach it. I started throwing water up with my hands. It wasn’t working. I ran to the house, but along the way, I saw Trigger (our dog)’s water bowl. I grabbed it and ran back to the fire. I filled the tiny dog bowl up probably 30 times and threw water up on the fire. When I decided I had gotten it to calm down, I knew it was only a matter of time before it would catch again. You can’t just turn off an 850°F oven—at least not this one that I had built.

I reached in my pocket and grabbed my phone. I held the button for Siri and said, “Siri, text Heather, bring me a water hose.” I laid the phone down and continued to throw water. A few moments went by, and finally, Heather came out. She was walking and didn’t realize there was an emergency. I yelled, “Bring me a water hose! This thing is about to burn up!” She quickly sprang into action, and I was able to get up on a ladder and pour water on the stovepipe to cool it down. The fire was stopped with very little damage.

It just adds character, right? I realized we had to fix this, but the pizza oven was still hot. There was nothing more we could do tonight. I told Heather we might as well go ahead and cook pizzas and fix the pipe later.

I checked the pizza oven temperature, and it was still sitting at around 800°F. I didn’t dare stoke the fire anymore but did go ahead and cook some pizzas for our friends. Cooking pizzas is hard. It happens quickly, and you have to turn the pizza. I wasn’t prepared on the first pizza but think it’s something that you get better at as you go. The second and third pizzas came out much better than the first.

All in all, the pizza was delicious, and we identified a large problem that had to be addressed. I called Johnny that night, and we laughed about the things that had gone wrong on the project and how nothing ever seemed to happen like this unless it was to me.

A few days went by and I decided to do a lot of research on stove pipes. Heather used the griddle for the first time cooking some smash burgers and they were fantastic.

What Now

I settled on 8” DuraVent DuraPlus Triple-Wall Stainless Steel Chimney Pipe. It ended up costing me about $1,500.00 to buy the stovepipe and the adapters to change over to the triple wall before exiting the top of the pergola. I have yet to get this done but have it scheduled now. The pipe will go out the roof of the pergola, which scared me until I thought about how many homes in the 1900s had stovepipes going out of their roofs. I bought the proper kit and will have professional heating and air specialists from Shelburne Heat and Air do the job. I’m going to leave the burnt spot as a reminder and a good story to tell folks enjoying the kitchen. I’ll post a follow-up when I’m done with the project and when I get the additional lights installed. Just like with most projects, nothing is ever quite finished. I’ll continue making improvements. I have plans to add some speakers, a few outdoor heaters, a wireless access point for that side of the yard, and possibly a television for trivia night. I hope to keep this page updated with progress and fun stories of things that I’ve learned while enhancing the structure. I don’t know that I’d ever recommend an outdoor kitchen of this magnitude to anyone, but I do know that I now have the experience to recommend how to install just about any one part of an outdoor kitchen to anyone who is interested.